MEMS and Nano Sensors

DiPaola Consulting is a leading expert in MEMS and Nano design, development and commercialization with over 25 years of experience. His nich is MEMS and Nano sensors in sports, biomedical / healthcare, transporation, consumer electronics, industrial and defense applications. Having mastered every phase of the new product development process at Texas Instruments, Sensata Technologies, TT Electronics and consulting, he has the knowledge to design and launch your sensor product right the first time. He also excels at integrating various system components including wireless functionality for successful deployment in the field.

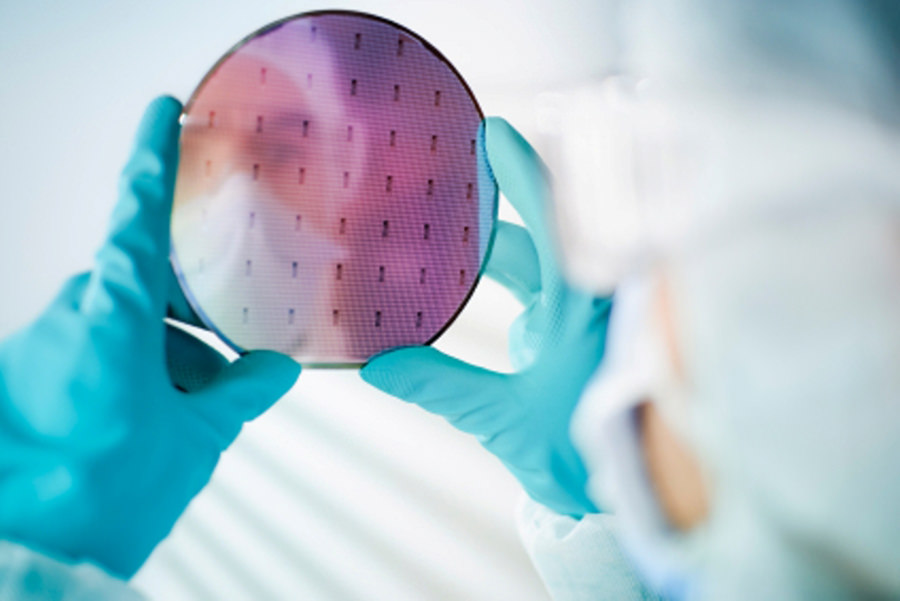

In developing a new product, one starts with proper evaluation and selection of the technology to be deployed in the product based on customer need. Doped silicon is often the technology of choice for electromechanical applications. DiPaola Consulting specializes in doped silicon applications with advanced modeling and analytical capabilities that include solid modeling, finite element analysis, MATLAB simulations, electrical models, ion implantation simulations and design of experiments.

MEMS and Nano sensor package design is a key consideration to ensure parasitic strains do not influence the accuracy of the sensor. Through several partnerships, DiPaola Consulting also provides MEMS prototyping services. We have excellent relationships with highly capable foundries to provide feedback during the design phase and technology transfer for design validation and production. Furthermore, we have developed key relationships with academic centers and renowned experts to stay informed of the latest MEMS and Nano advancements.

Our extensive experience has taught us that the core elements of the technology must be designed concurrently with the sensor packaging and system integration. The most important aspects of this design process entails keeping out the environment, eliminating or minimizing packaging effects on device performance, ease of manufacture, creating an intuitive and practical user interface and making it robust to external forces that may result in damage or malfunction. We excel at providing solutions to some of the harshest safety critical applications in the industry.

With our history of developing products and processes with next to zero field failures, we recognize that process development and product validation are key aspects to achieving low cost and high reliability. In every phase from concept to final design validation, process development and device testing provide continual feedback for design improvements. We ensure that each process is capable from the start through rigorous research, parameter variation, capability measurements and fundamental validation.

We also believe in product testing to failure and not just to the customer specification to fully understand the inherent weaknesses of the product. Through these rigorous and field-tested principles and methodologies, we consistently exceed customer expectations in the design and commercialization of our MEMS and Nano sensor products.